I didn’t set out to become a High-Performance HVAC™ craftsman. Like many others, my career began by doing what I thought was good work, solving problems the best way I knew how, and trying to make a living in an industry that can be equal parts rewarding and frustrating.

I learned quickly that it’s not just about replacing boxes. It’s about understanding systems — how they breathe, how they move air, how they succeed or fail based on decisions made by everyone from carpenters to sales reps.

Somewhere along the way, I realized the industry I loved was being driven into mediocrity — not by malice, but by momentum. Bad habits became standard practices. Systems were oversized, ducts were undersized, and comfort became a crap shoot. That didn’t sit well with me. It still doesn’t. And it shouldn’t sit well with you, either.

The Wrong People Defining Our Work

One of the most eye-opening lessons I have ever learned is that most HVAC system sizes aren’t based on engineering principles.

They’re based on what fits in between the trusses. Trusses are typically spaced 24 inches on center, so HVAC equipment manufacturers design their equipment to be less than 21.5 inches wide to slide into place. That’s it. That’s the reason.

And because the unit is less than 21.5 inches wide, the return filter slot is cut to 20×25 inches or, at best, 20×30 inches or less.

That’s the number stamped on the door, so that’s what we install. Never mind that this setup is almost always undersized and that filters with too much resistance force air to go around rather than through. We were taught not to question it. But once you understand the reason, you can’t unsee it.

In other words, we’ve let carpenters and architects define how HVAC systems perform. That’s not just wrong, it’s dangerous. Comfort, efficiency, and performance are dictated by a framing layout. That must stop.

Here is where you can start. Calculate the area of any filter and multiply by 2. The result is the maximum air flow for proper filtration.

For example, 20 x 25 = 500, 500 x 2 = 1000 cfm max, or a 2.5-ton system limit. This size is commonly found in a 5-ton air handler, and it is one half the size it should be for best airflow filtration. Use two filter grilles on all five-ton systems!

A High-Performance HVAC Craftsman’s First Priority: The Airway

Every first responder knows that when someone collapses, you check their airway first. You don’t check their pulse, you don’t start chest compressions — you make sure they can breathe. Air is life.

It’s no different in HVAC. If the system can’t breathe, it can’t work. Yet I see it all the time — returns that are half the size they need to be, ducts so undersized they could choke a squirrel, and filters crammed into cabinets like an afterthought.

I teach the following HVAC principle in every class: “Air follows the path of least resistance.” That means if you force it through a high-pressure filter or a narrow return, it will find a new path, usually one that bypasses the very components intended to clean and condition it. The result? Dirty coils, unhappy customers, and systems that under perform from day one.

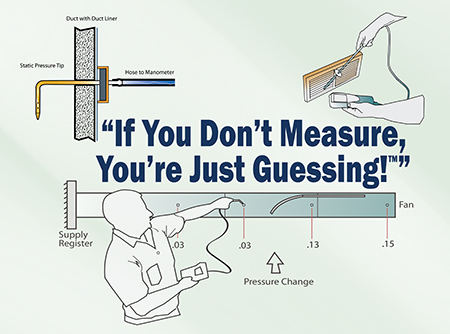

The Numbers Don’t Lie

Here are some sobering statistics: National Comfort Institute (NCI) discovered that 57% performance is the norm for residential HVAC systems. That means homeowners are getting just over half the heating or cooling they paid for.

Why? Think about this: 42 states adopted codes equivalent to IECC from 2009 to 2018. Twenty-nine states require contractors to use Manual J to size equipment. Yet, only around five percent of HVAC contractors use Manual J. The rest are guessing — or worse, copying what the last guy did.

Builders ask, “How much per ton?” Contractors respond by cranking up the tonnage to make the job profitable.

The result is that most air conditioning systems are 50% oversized and still uncomfortable. It’s a vicious cycle. That is NOT High-Performance HVAC!

Add to that the reality that the median home in America was built in 1984. That means half the housing stock is outdated by energy code standards. And while homes have become tighter and more efficient, HVAC sizing practices haven’t kept up. We’re still applying 1970s rules of thumb to 21st-century homes.

Guessing Isn’t Good Enough Anymore

To quote Henry Ford, “If you think you can, or you think you can’t, you’re right.” Ford’s truism is also valid in the HVAC Industry.

Our training says that some problems are “the way things are.” But they’re not. They’re solvable. You need to learn how.

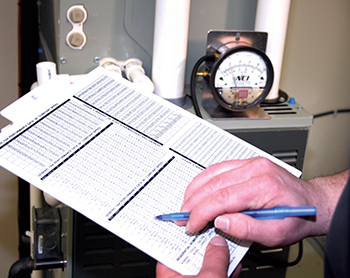

Years ago, when I was working with Austin Energy, a Texas utility, we did everything by the book. That means we performed Manual J calculations, duct sealing, the whole program.

When I measured performance, we hit 62%. That was with everything done “right.” Imagine what the rest of the industry was and still is delivering.

That’s when I challenged their staff to come out and measure with me. I wanted them to see that following the rules still doesn’t guarantee good performance. You need to exceed them. This means you need to think like a craftsman.

You Can’t Teach What You Don’t Know

I often say that success is a byproduct of craftsmanship. You don’t chase it, you become it. And once you know the truth, you begin to understand the confusion.

I remember reading an article in a trade magazine — back when I was in the weeds trying to sort through bad information from professors who had never touched a furnace.

The article had math that actually worked. That blew me away. I called the magazine, talked to Dominick Guarino, and found someone who could answer my questions. That was my turning point.

You can’t teach what you don’t know. And you won’t learn it unless you admit you need to. That’s why real High-Performance HVAC craftsmanship begins with humility. The most competent techs I know are the ones who admit they’re always learning.

Apprenticeship Is the Missing Link

We’ve lost something important in this trade — apprenticeship. Plumbing has it. Electrical has it. But in residential HVAC, it’s a rare thing. Trade schools are resurfacing, and more contractors are beginning to develop their own technicians, but it’s still not enough.

Craftsmanship can’t happen without mentorship. And yet our highest-performing techs often make the worst trainers. Why? Because they’re on performance pay, they’re in a rush, and they don’t want to slow down to explain things. We need to reward teaching, not just doing.

If you’ve got a great tech, pair him with someone eager to learn — and compensate them both. It’s not just about completing tasks more quickly. It’s about building a team that can sustain itself, grow, and consistently deliver high-quality work.

Don’t Be a Box Swapper

Here’s the truth: anyone can replace a box. The industry is full of “box swappers.” They yank out the old equipment, drop in the new one, and call it a day.

But if you never ask the customer what they want, if you never diagnose the airflow, and if you never match the system to the ductwork or the building load, you haven’t fixed anything. You’ve just reset the timer.

True craftsmen don’t just sell solutions; they create them. They solve problems. That starts by asking the customer: “What are your expectations today?”

You’ll be amazed at what you hear. Some want it done quickly, regardless of the cost. Others are flipping the house and want the cheapest Band-Aid® possible. But if you don’t ask, you’ll never know.

Quote of ancient Greek philosopher Aristotle.

A System Is More Than the Sum of Its Parts

I’ve spent a lot of time teaching techs that air doesn’t behave the way we think. Have you heard of the Coandă effect? It’s the principle that air will follow a curved surface. Without it, airplanes wouldn’t fly. And without understanding it, our ducts won’t work.

If your ductwork turns like a brick, your airflow is going to be noisy and inefficient. Air wants to move gently, following curves and wide angles. That’s why turning vanes exist. That’s why square corners kill performance.

These aren’t just theoretical concepts. They affect every job you do. If you can’t move air properly, your system won’t function, regardless of how efficient the equipment is.

The Time Is Now

Here’s what keeps me up at night: 40% of our skilled workforce is about to retire in the next five years. That’s not a forecast — it’s happening now. We’re at a crossroads.

We can keep swapping boxes, guessing on sizing, and praying for fewer callbacks. Or we can start teaching, mentoring, learning, and building systems that perform at 90% or more of their potential. We can be High-Performance HVAC craftsmen.

But we must choose it. Nobody’s going to force us. The industry won’t evolve unless we evolve first.

Success Is Something You Earn

Viktor Frankl once said, “You cannot pursue success; it must ensue.” Success isn’t about money, trucks, or marketing campaigns. It’s about earning pride in your work, knowing you’ve solved a real problem for someone, and having a system that works the way it should.

You can’t fake that. You can’t outsource it. Each contractor must build it one job, one duct, one apprentice at a time.

If you’re tired playing by someone else’s rules, if you want to become more than just a mechanic, start asking different questions. Start learning what you don’t know. Start evolving. This trade doesn’t need more installers, it needs more High-Performance HVAC craftsmen.

Paul Wieboldt is the president of Tradewinds Appropriate Technologies, Waco, TX. He also founded a private school, worked as a curriculum developer, and developed a passion for teaching. In the mid-1980s, he relocated to Texas and began his career in the HVAC industry. Several years later, he discovered NCI and was able to combine his experiences into a teaching focused on environmental comfort and health. You can contact Paul at ncilink.com/ContactMe.

Reprinted from the September 2025 NCI High Performance HVAC Newsletter