My dad started GVs Heating and Cooling in 1990 before I was born. You can say I was raised in the HVAC industry. As a child, I asked him to take me to work every year on Take-Your-Daughter-To-Work Day.

So, it was no surprise that in 2006, I decided to join the family business, doing odd jobs around the office, and eventually, somewhat reluctantly, took sales training at the recommendation of our Trane territory manager.

TRAINING CHANGED EVERYTHING

That changed everything for me.

Fast forward to 2017, when I earned my first certification from the National Comfort Institute (NCI) Commercial Air Balancing class with Scott Fielder. To this day, I haven’t looked back. This class changed my perspective on implementing a High-Performance HVAC approach to contracting.

The result is that GVs Duct Renovation Installations have taken on a life of their own over the last few years through customer referrals and service technician leads.

taking static pressure and

temperature drop

measurements, among several

other tests.

The best part about being a Comfort Specialist is evaluating a client’s comfort system and collecting the data. I don’t only do furnace or air conditioner equipment changeouts. Frankly, that got a little too boring.

The high-performance approach makes my job fun because I solve problems no other contractor can solve!

Recently, I had the privilege of presenting an educational seminar with NCI’s Dominick Guarino at the AHR Expo in Chicago.

During our presentation, titled “Why and How to Sell High-Performance HVAC,” we discussed three types of sales calls:

- Traditional Replacement Leads

- Service-Generated Call Turnovers

- Homeowners Seeking Solutions.

FINDING REAL SOLUTIONS THROUGH SYSTEM EVALUATION IS MY FAVORITE SALES CALL

During that session, we asked the audience which type of sales call was their favorite. For me, hands down, my favorite is the last one — working with homeowners seeking solutions.

Over the last few years, I’ve received multiple leads for homeowners who newly renovated their homes or built a brand-new home that had comfort issues. They were irritated with hot and cold rooms, furnace/air conditioners not running efficiently, furnaces not running safely, and high utility bills.

Imagine how frustrating this would be, especially if the problems happened in a brand-new house!! In one case, the customer gave up on the installing contractor and just wanted a solution.

CASE STUDY: THE SILVER HOME

This client, The Silver family, lived in their newly constructed home for about six months before experiencing extreme room temperature differences on the second floor. This home had two systems: a basement furnace (provided heat for the basement and first floor) and a furnace located in an attic to condition the second floor.

Mr. Silver provided a tour of the second floor, pointing out that the storage room and kid’s playroom were extremely cold during winter. I will never forget how, after pulling down the attic access ladder, I was hit with a breeze that blew my hair like a fan was blowing on it! I was so excited to dive deep into evaluating this system.

So, where do you start? Using my High-Performance HVAC™ training, I always evaluate homes from scratch, testing and measuring to collect all the data necessary to provide a solution.

This from-scratch evaluation means performing a Manual J room-by-room load calculation, measuring static pressure and temperature rise, and taking supply temperatures in each register.

I also measure return temperatures at each return grille, measure all ductwork, and count how many supplies and returns are in each room.

This process also includes measuring airflow and evaluating blower wheel conditions and speeds. Performing these diagnostic tests takes about two to three hours, depending on the extent of the diagnostics. While doing these tests, I always try to include the homeowner and then teach them what our measurements mean. This can be very eye-opening for them.

I collect all the data, take pictures and videos of the furnace and ductwork, then start the evaluation.

AFTER THE EVALUATION: OUR FINDINGS

When evaluating Mr. Silver’s furnace, I saw the system going off on limit, which made me immediately think this was why the system wasn’t heating some of the rooms in the home.

The Silver furnace was installed upright in a “room” in the attic. The height of the supply plenum off the evaporator coil was only seven inches high! How could the air remove the heat from the heat exchanger?

It couldn’t!

I measured a 148°F supply temperature and a 79°F return temperature (69°F Delta T). This furnace was rated for 35-65°F.

The return trunk was “slapped” to the side of the furnace with a filter that was wide open to the attic, along with a bypass humidifier on the return trunk. The system was performing within the static pressure range, but after further inspection, I also found duct leakage as a culprit. That clarified why my hair was moving after opening the attic access.

After collecting all the data, measurements, pictures, and videos, it was time to assemble a solution.

How do you educate your client and present your solution? During the day of the evaluation, there is a lot of information for the client to absorb. At GV’s Heating & Cooling, we put together a Performance Report. In this report, we number each issue and include a corresponding remark and pictures.

RESULTS DETAILS

For the Silver Residence, we discovered the following seven issues:

- Supply Plenum was restricting airflow

- Return Air Drop was restrictive, and the filter was open to the attic

- The Evaporator Coil was only an up-flow coil

- The Supply Trunk was undersized for the east side of the house (Master/Storage room and playroom)

- A dirty Blower Wheel

- The furnace was short cycling, going off on limit due to low airflow, restrictive supply/return, and bypass humidifier on return

- Smelled gas – found numerous gas leaks by the furnace.

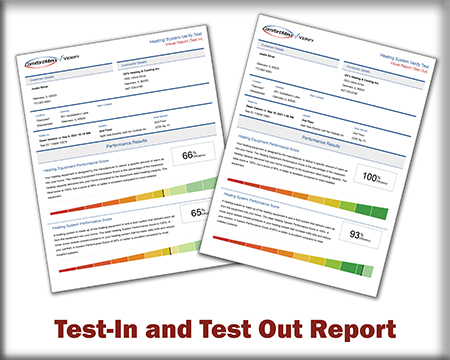

Along with this report, I also attach a “Test In” Visual Report from ComfortMaxx™. ComfortMaxx is a third-party software-based system evaluation and verification test. Using this software, I found that the Silver residence had the following:

This system required a fan airflow of 1,200 CFM, but I measured only 658 CFM. This brand-new system only performed at 55% of the required fan airflow.

GV’S EVALUATION AND SOLUTION PROPOSAL

How many times do we go into a home and have tunnel vision? We only see what is in front of us. I want to give a shout-out to NCI’s John Puryear, who, during a class he was teaching, mentioned that just because you see a furnace in an up-flow position, it does not mean it has to stay that way. He said, “We have to go into these homes and open our vision to a new perspective.”

In this situation, I did just that at the Silver’s home.

The furnace “room” was only 7 feet wide x 7 feet deep x 5 feet 2 inches high, After our evaluation, I knew the way the furnace was installed was not working. In this case, there was more room horizontally than vertically.

We needed to uninstall the furnace, evaporator coil, and ductwork in the utility room. The good news was that Silver’s furnace and air conditioner were sized correctly. The only piece of equipment GVs had to replace was the evaporator coil because it could not be installed horizontally.

NO MORE BLOWING HAIR!

By re-installing the furnace in a horizontal position, adding a new supply plenum, increasing the supply trunk to the east side of the home (main suite, storage room, and playroom), adding a properly sized return duct, installing a new automatic humidifier, sealed filter cabinet, and sealing all the ductwork, we drastically increased this system efficiency.

The ComfortMaxx “Test Out” scored a Heating Equipment Performance Score of 100% and a Heating System Performance Score of 93%. The system was now delivering 1,139 CFM!

Plus, our solution eliminated the excess attic pressure. We no longer have blowing hair!

Dawn Mroczek is the comfort specialist at GV’s Heating & Cooling in Buffalo Grove, IL. In 2007, she moved into the sales position. She is certified in Commercial Air Balancing, Duct System Optimization, and was recognized as one of the ‘Wonderful Women in HVAC Sales’ with Sharon Roberts. She is also the 2020 recipient of NCI’s High-Performance Sales Excellence Award. You can reach out to her with questions at ncilink.com/ContactMe.