|

By:Luke Peterson

This tech tip was written by Luke Peterson, the president of The Maintenance Department in Louisville, KY. Luke was a speaker at the 5th Annual HVAC Training Symposium in 2024 and has been on HVAC business panels at the symposium in 2023 and 2024. Thanks, Luke!

As an HVAC technician, your primary goal is not just to fix machinery; it’s to make homes and people comfortable. This lesson became crystal clear to me during a challenging project in South Carolina. Here’s what I learned and how these insights can help you succeed in the ever-evolving HVAC industry.

The Project: A High-Efficiency HVAC System in a Troubled Home

In 2022, a friend of mine in a climate zone 2-3ish part of South Carolina* reached out because their old heat pump system had finally gone to be with the Lord. Always ready to lend a hand, I installed a high-efficiency 18-SEER inverter heat pump and air handler from Amana (for reference only). But not long after, my friend started experiencing comfort gaps and seeing errors on the control board.

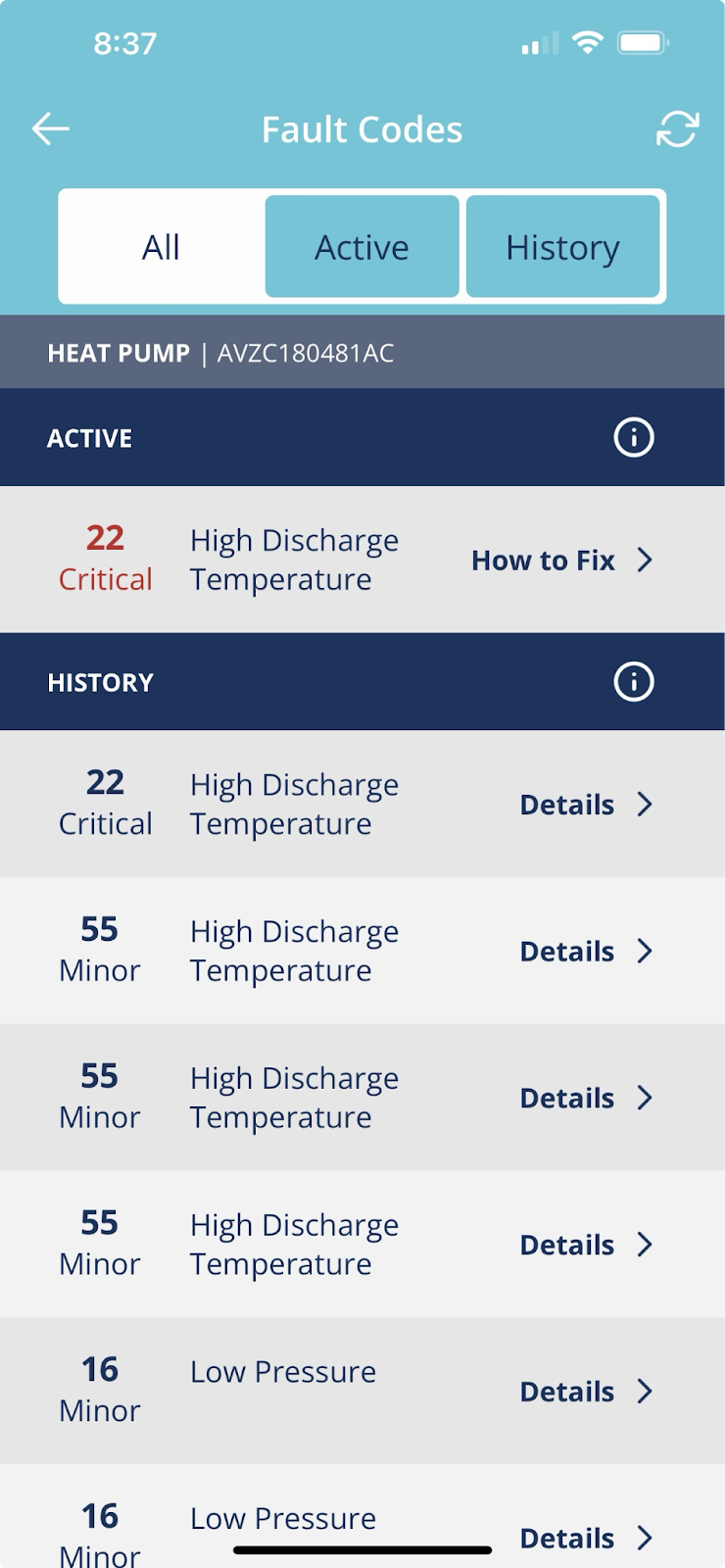

After fixing some minor issues, a persistent high compressor discharge temperature error left me stumped, especially since it only occurred under certain ambient outdoor conditions, 60–65°F.

*(Depending which map you use: source: https://basc.pnnl.gov/sites/default/files/images/IECCmap_Revised.jpg)

Realizing the Bigger Picture: A House is a Duct! A Door is a Damper!

Initially, I zeroed in on the HVAC system, even considering full system replacement. However, this option would be costly and possibly result in persistent issues again. So, I decided to take a step back and analyze the house itself. The house had two returns: one in the stairwell and one in the bonus room over the garage, the most comfortable room in the house! The doors in all the bedrooms were closed 80% of the day, which blocked off well over 50% of the house—and effectively the duct system—when all the doors were shut.

Using a zone pressure test, I found significant pressure imbalances (5.0-6.6 Pascals) whenever the bedroom doors were closed, and the home had persistently high humidity levels. With the thermostat reading around 76% relative humidity, it was clear that ductwork was a major issue.

The Importance of Understanding Airflow and “Smart” HVAC Appliances

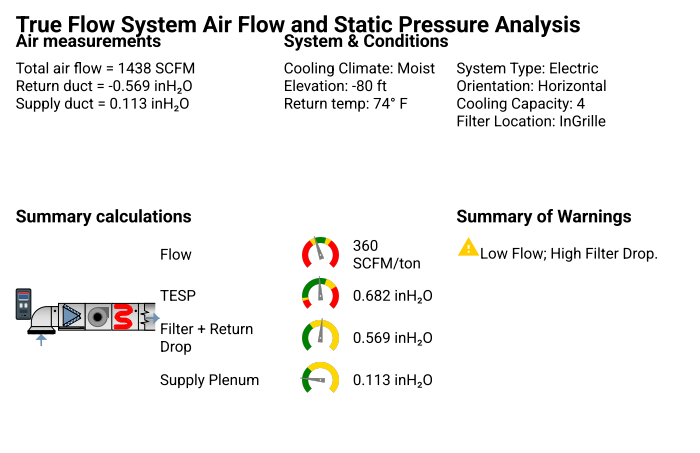

To get a fuller picture, I asked the homeowners detailed questions about their comfort levels, door usage, and specific room conditions. Using The Energy Conservatory’s Digital TrueFlow® Grid, I measured the HVAC system’s airflow. The results showed a notable, though not drastic, difference in airflow with doors open versus closed. This led to a key realization: variable speed motors in the HVAC system were compensating for duct and building issues by ramping up, causing high static pressure, and pulling in unconditioned air from outside. Essentially, the highly regulated system was protecting itself from failure because the house’s duct system was inadequate.

A critical factor in the system’s behavior was the internal superheat controlling algorithm or PID loop, which maintains proper superheat. Most EEVs are designed to operate down to a fully closed position, with their operation controlled by the unit programming. This process is intended to maintain superheat at whatever stage the compressor is running. Because of a lower heat load and lower (inhibited) airflow, the compressor would downcycle and the EEV would close to maintain saturated levels in the evaporator. However, this caused the compressor to receive insufficient vapor cooling and increase the compression ratio, leading to high compressor discharge temperatures.

Furthermore, in this diminished low load state, the system would run an oil return function that opens the EEV to 100% and runs the compressor at 100%, essentially flooding the evaporator to gather oil retained during low refrigerant flow periods. This issue played a part in triggering the E22 CRITICAL High Discharge Temperature error and subsequent shutdown. It was not a fault of the system itself but rather a consequence of insufficient thermal load at the air handler. The HVAC system was doing everything it could to protect itself from catastrophic failure given the house’s duct conditions. This problem was especially prevalent during the shoulder seasons when the heat load was low.

These issues are showing up now because the new system is an advanced inverter unit with safety controls that monitor and protect its internal components. Unlike the old single-stage unit, which ran when the thermostat called for it to run, and eventually failed, the new system responds to airflow problems by shutting down or underperforming to prevent damage.

Taking Action: Practical Steps to Improve Comfort

Realizing the extent of the problem, I knew actionable steps were needed. By slowly opening the door, I measured the cross-sectional areas required for transfer return grilles as the room pressure reached 0.0 Pa in each bedroom. The homeowner and I cut in the allotted holes, and using a smoke wick pen, we verified airflow and installed return grilles. (Verifying air flow through the wall space prior to adding the grilles is important because we found that there was non-structural blocking in two of the walls that had to be removed.) This step significantly reduced pressure imbalances and improved airflow (see data below). NCI’s David Richardson likes to say, “It’s about progress, not perfection.”

A few days later, my friend reported immediate improvements in comfort, though they initially felt their house was too cold. This feedback confirmed that the adjustments were effective in achieving consistent temperatures and reducing humidity levels.

Key Takeaways for Young HVAC Technicians

1. Learn to Measure Airflow: As HVAC systems become more energy-efficient and sophisticated, your knowledge of the relationship between airflow and HVAC appliances must increase. If you don’t know how to measure airflow or understand air movement within a house, there are great resources at https://hvacrschool.com/?s=airflow. Understanding how air moves and delivers comfort is crucial.

2. Embrace the Building Sciences: A house is a box that defies nature every day of the year! So, invest time in learning building science. Resources like Alison Bailes’ book A House Needs to Breathe, or Does It? are invaluable. Understand that many builders don’t know the intricate relationship between air, water, and structure as it relates to HVAC.

3. Do Not Avoid High-Efficiency Systems: Shying away from high-efficiency inverter systems is not the answer. These systems will become standard in the coming decade. Understanding how to work with them and optimize their performance in different building conditions is essential.

Conclusion: Focus on Comfort, Not Just Machinery

At the end of the day, our job is to make homes and people comfortable. By understanding the principles of building science and airflow, you’ll not only become a successful HVAC technician but also ensure that your clients enjoy the true benefits of their HVAC systems.

Remember, each house is a unique system with its own set of challenges. The more you understand about airflow and its effect on a building enclosure, the better equipped you’ll be to handle these challenges. So, take the time to learn and grow in your knowledge for the sake of your future self—and your clients. They will thank you for it.

Before (doors closed)

After (with returns)

—Luke Peterson

Co-Founder and President at Kalos Services, Bryan Orr has been involved in HVAC training for over 13 years. Bryan started HVAC School to be free training HVAC/R across many mediums, For Techs, By Techs.

Contact Bryan by emailing bryan@HVACRSchool.com.

Visit https://hvacrschool.com – The place to learn some things you’ve forgotten along the way as well as remind you of some things you forgot to know in the first place. |